- Overview

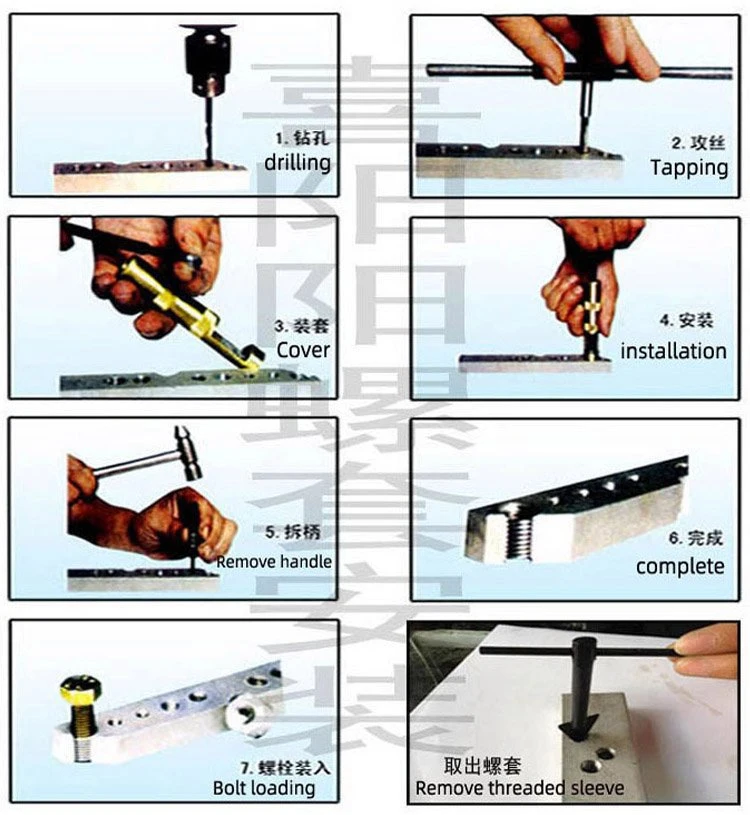

- Installation Instructions

Basic Info.

Model NO.

M2-M100

Surface Finishing

High-Speed Steel

Certification

ISO, RoHS

Customized

According to Customer Requirements

MOQ

100 PCS

Thread Accuracy

6h

Name

Wire Thread Insert

Nominal Length

1d-3D

Transport Package

Carton

Specification

ST6*1

Trademark

XYY

Origin

China

HS Code

7318190000

Production Capacity

500pieces

Packaging & Delivery

Package Size

14.50cm * 8.50cm * 10.50cm

Package Gross Weight

0.045kg

Product Description

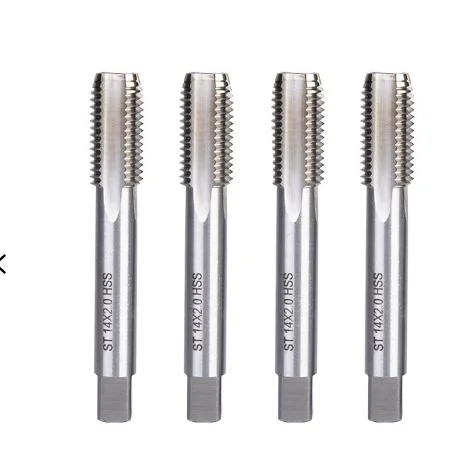

Xiyangyang Steel Wire Screw Sleeve Tap is used to process blind hole bottom hole. It can produce chips quickly and has high precision. It can process the bottom hole.

Xiyangyang Steel Wire Screw Sleeve Tap is used to process blind hole bottom hole. It can produce chips quickly and has high precision. It can process the bottom hole.

| M2.5*0.45 | 2.6 | M10*1 | 10.3 |

| M3*0.5 | 3.1 | M10*1.25 | 10.3 |

| M4*0.7 | 4.2 | M12*1.25 | 12.3 |

| M5*0.8 | 5.2 | M12*1.5 | 12.4 |

| M6*1 | 6.3 | M12*1 | 12.3 |

| M7*1 | 7.3 | M13*1.25 | 13.3 |

| M8*1.25 | 8.3 | M14*1.5 | 14.4 |

| M10*1.5 | 10.4 | M14*1.25 | 14.3 |

We often use: straight groove tap, spiral groove tap, screw tip tap, extrusion tap, its performance has its own strengths.

Straight groove tap has the most versatility, through holes or through holes, non-ferrous metals or ferrous metals can be processed, and the price is also the cheapest. But the pertinence is also poor, anything can be done, nothing is the best. The spiral groove tap is more suitable for processing through the hole thread, and the chip is discharged backward during processing. Because of the screw Angle, the actual cutting Angle of the tap will increase with the increase of the screw Angle.

Experience tells us: for the processing of black metal, the helix Angle is a little smaller, generally around 30 degrees, to ensure the strength of the helix teeth. Processing of non-ferrous metals, the spiral Angle is selected a little larger, can be about 45 degrees, and the cutting is sharp. The chip is discharged forward when the screw tip tap is processed. Extruded tap is more suitable for processing non-ferrous metals.